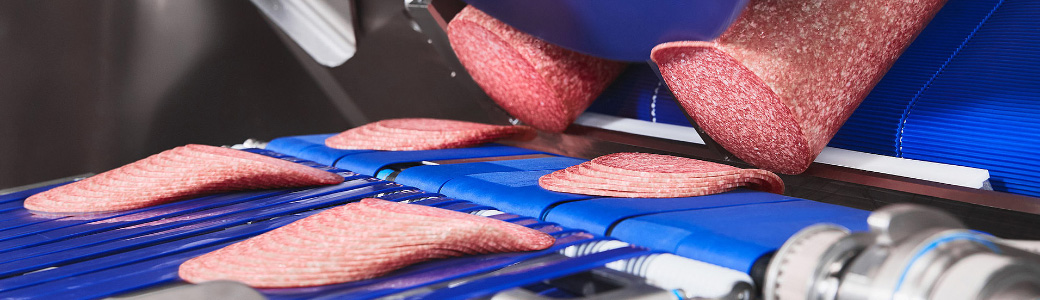

Bearings for the food industry

Food production is one of the most demanding equipment sectors of human activity. Bearings for the food industry must be not only effective, reliable and easy to maintain, but also meet sanitary standards. ROLEK also pays great attention to the resistance of its products to external influences. To improve the characteristics of roller bearings and ball bearings, modern materials and innovative technologies are used.

The Czech manufacturer ROLEK has long begun to develop support parts for the food industry. Each special ROLEK bearing was created taking into account the fact that negative factors will act on it during operation: acidic environment, abrasive materials, high humidity, temperature changes. Previously, it was believed that the ideal material for working in such conditions is corrosion-resistant steel. But just a stainless bearing assembly today does not satisfy all consumer needs, so the brand proposed a new type of product in which steel is protected by a special coating.

ROLEK bearings for the food industry have the following important advantages:

- Made of special resistant steel created by SKF specialists for use in agriculture and food industry;

- The products use multilayer rubber seals with a low coefficient of friction, the use of which prevents contamination of the surfaces of the part and loss of lubricant;

- Each unit uses a lubricant approved by the Food and Drug Administration (FDA);

- New bearings are self-aligning, so that their work is most effective even with misalignment.

The lubricants for the new ROLEK food bearing series are synthetic and washout resistant. They are devoid of taste and smell, and also do not contain toxic components. Equipment in the nodes of which this type of lubrication operates can be used for processing meat, fish, fruits, vegetables, spices and dairy products without any restrictions.